Aziende Industriali di Lugano

Digitization of metering and maintenance from a single source

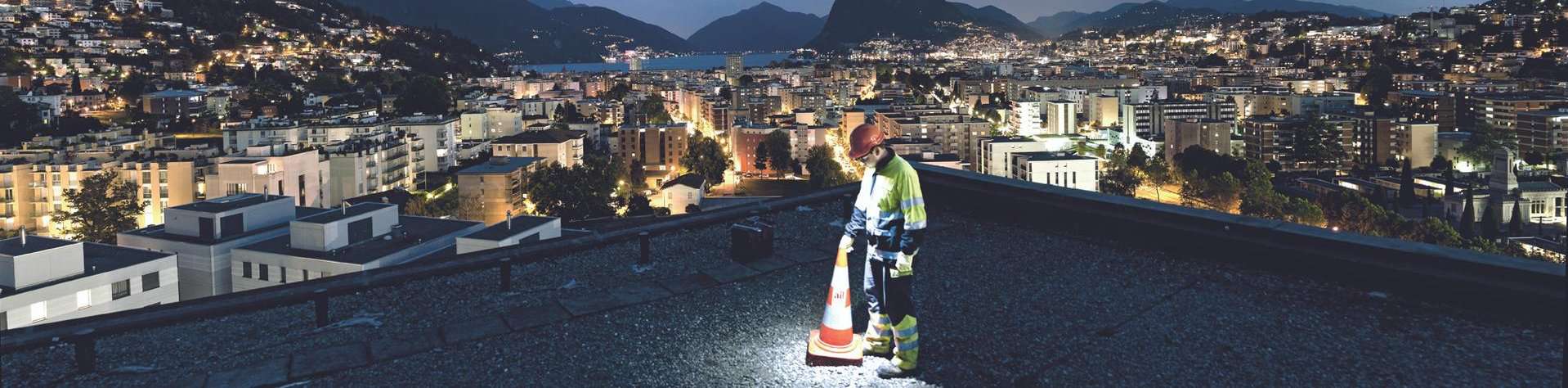

Aziende Industriali di Lugano (AIL) provides comprehensive energy services to its 113,000 customers in the canton of Ticino plus neighboring regions in southern Switzerland. 382 employees ensure a smooth supply of electricity, water, heat and gas. 66 percent of the electricity comes from renewable sources.

52 technicians work in construction and maintenance and in metering. They process around 40,000 orders a year. Of these, 32,000 are from the metering area, i.e. readings, installations or changes of equipment. 8,000 orders are for network maintenance and inspection. Five dispatchers plan the assignments of the technicians and meter readers centrally from Muzzano, the company’s headquarters.

Digitization of dispatching and order processing

In order to digitize the processes of dispatching and order processing in maintenance and metering, AIL conducted a tender for a field service management solution in 2013. This was to replace and accelerate the previous manual order distribution and processing. For metering, there was already a mobile solution for reading, but it was getting on in years. Until then, the schedulers planned all other orders in the metering area and in maintenance directly in SAP IS-U and in SAP PM and then printed them out for the technicians. The technicians also created the confirmations on paper. The subsequent manual transfer by the office staff into SAP was correspondingly error-prone.

Integration with SAP and use in metering played a major role in the selection of the new field service management system. Therefore, the decision was finally made in favor of mobileX, which offered a special solution for metering. In addition, mobileX met the tender criteria and offered the best price-performance ratio.

Deployment of the Field Service Management Solution in Metering

The implementation of mobileX’s Field Service Management solutions started in 2014 with metering, as this is where most of AIL’s orders are generated. In 2016, the area was productive with all 42 technicians and part-time staff performing meter readings. A special feature at AIL is that many of the customers’ keys for meter readings are available at AIL. That’s why these jobs are usually scheduled the day before. More complex jobs, such as a meter swap, are performed by the technicians and scheduled about a week in advance. So far, 8,500 smart meters are in use at AIL’s customers. Some of these are already being read remotely. According to the law, 80 percent of all analog and digital meters in Switzerland must be replaced by smart meters by the end of 2027.

Since 2016, the schedulers in the metering department have been planning all orders for meter readings as well as meter changes, installations and removals in the mobileX-Dispatch scheduling tool. Using route optimization, they can put the orders of the technicians and meter readers in a sensible order and thus plan the shortest possible walking and driving distances.

The colleagues now receive their orders in the mobile solution mobileX-MIP for Metering on their Android tablets. They also use it to record the meter readings and create the feedback reports, which are then transmitted directly back to the back office. The technical warehouse for the meters is also digitally mapped in the mobile solution. For confirmations of meter changes as well as installations and removals, a check takes place via the so-called Confirmation Center before posting in SAP. This is an intermediate instance into which confirmations can be routed according to certain criteria and checked by the office staff. This avoids time-consuming reversals of incorrect postings in SAP.

Optimization of maintenance processes

The rollout of digital deployment planning and order processing in the Construction and Maintenance division began in 2019 with the Electricity division. Here, the focus is on regular inspections of facilities such as distribution boxes, transformer stations, or network installations, which are now planned and distributed via the dispatching solution. The Dynamic Forms module, an extension for mobileX-MIP for Field Service, is used for processing maintenance plans. This allows technicians to digitally edit checklists and forms on their laptops. Like their colleagues in metering, they now receive their orders in the mobile solution and also create their feedback via it.

Conclusion: Improved transparency and data quality

After five years of productive use, Giorgio Buzzi, Program Manager at AIL, draws the following conclusion: “The use of the scheduling solution has significantly improved transparency in planning. The technicians now no longer have to come to the office to pick up their orders. The mobile solution and the digitization of documents, as well as the control provided by the Confirmation Center, have also noticeably increased the quality of our data.”

Outlook

AIL is currently preparing to roll out the mobileX solutions for the gas and water divisions as well. After the complete rollout in all divisions, unplanned processes such as malfunctions should also be handled with the mobile solution in the future. Furthermore, the introduction of the mobile app mobileX-CrossMIP for the maintenance division is being planned.

Aziende Industriali di Lugano (AIL) SA is the largest electricity, gas and water utilities in the canton of Ticino. Continuous work in the service of customers and the desire to offer the company products in the best technical and economic conditions, are the main objectives of the company.