Maintenance software to digitize your processes

Order planning with Excel lists and order processing with paper were yesterday! The digitization of maintenance processes eliminates media discontinuities and error-prone, manual data transfers. The benefits that software can bring to maintenance quickly become apparent: higher plant availability, more transparent and efficient maintenance processes, and higher data quality.

Our solutions accelerate maintenance processes and make them more transparent and audit-proof. Maintenance planners always have an overview of the maintenance orders and the workload of the maintenance staff.

More efficient processes shorten downtimes for maintenance, inspections and repairs of plant and machinery. This increases plant availability and ensures maximum productivity.

The digital capture of data at the plant increases data quality and forms the basis for optimal maintenance planning, maximum machine service life and higher profitability.

Our maintenance offering consists of the following products:

Order planning software

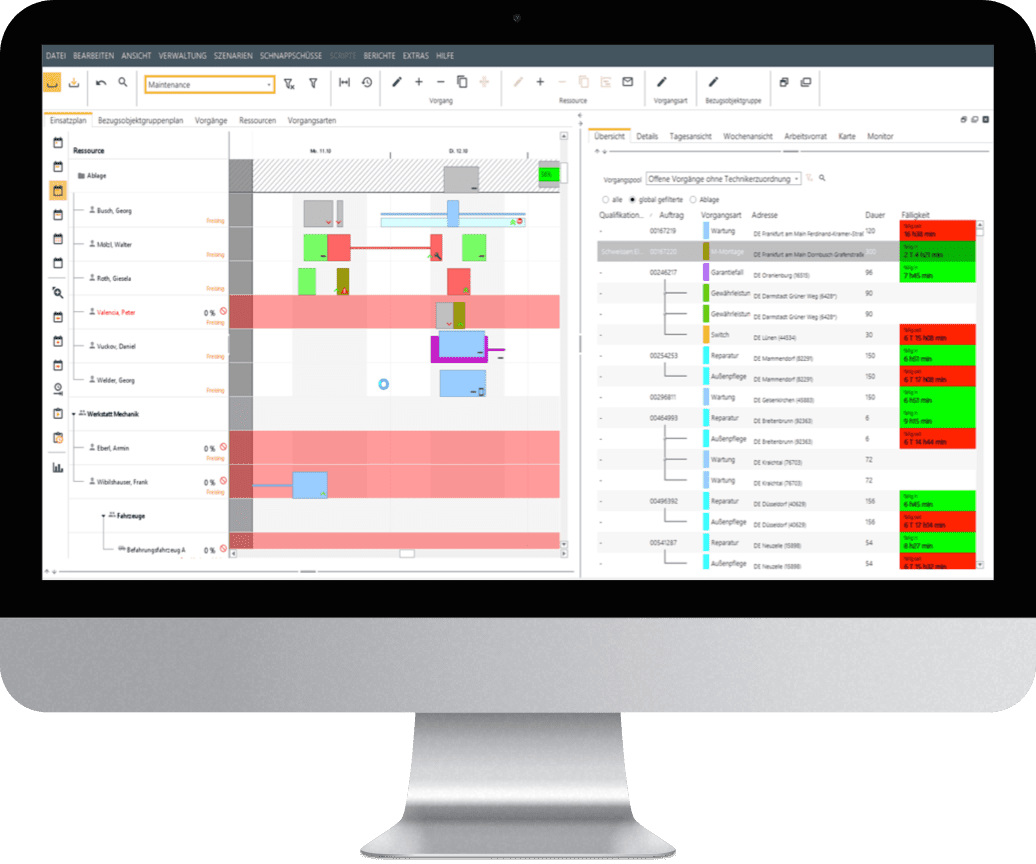

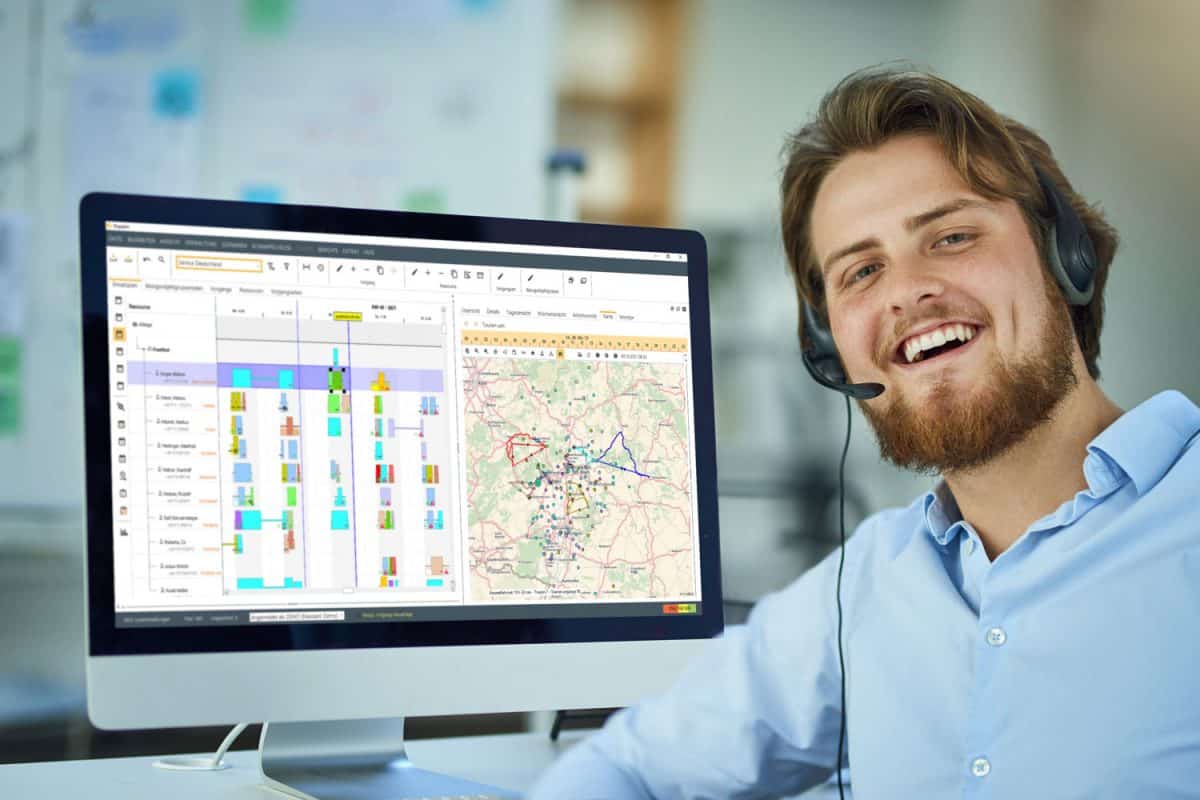

mobileX-Dispatch is our tool for optimizing your order planning for maintenance. Our digital planning includes the dispatching of orders according to qualifications, route optimization, manual planning via drag and drop as well as semi- and fully automatic planning. Pool planning and dispatching of orders to external service providers is also possible with mobileX-Dispatch.

Maintenance app

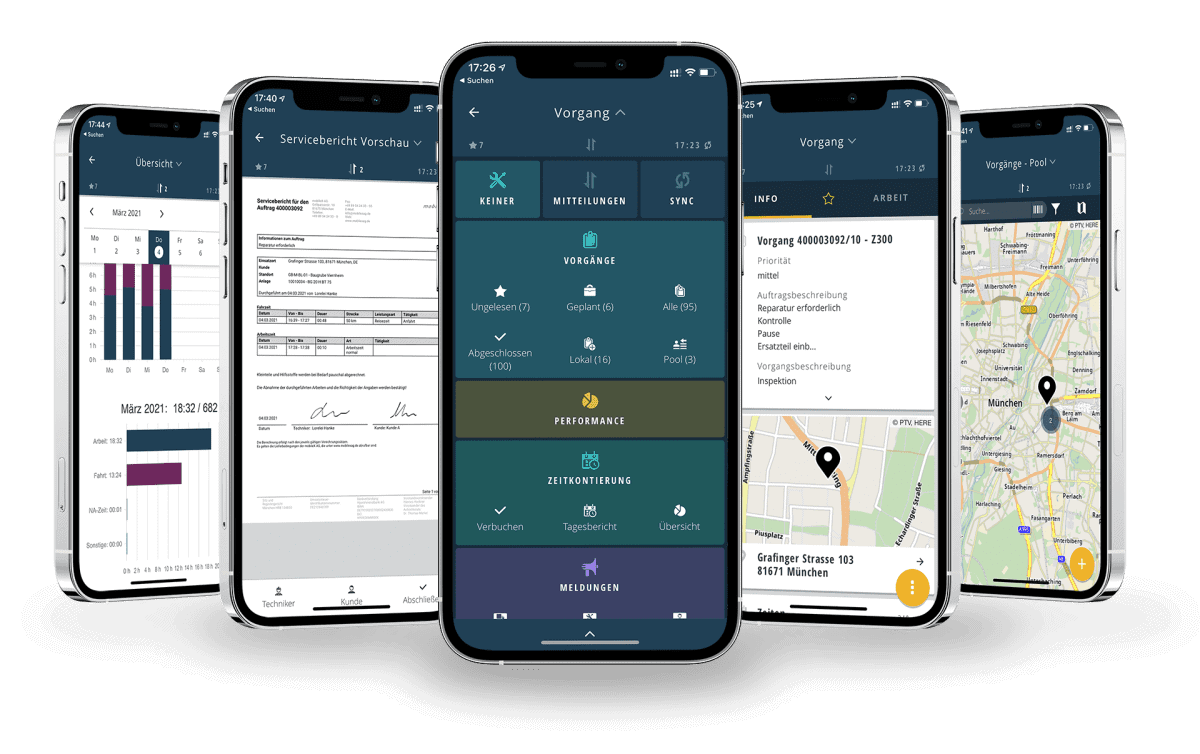

mobileX-CrossMIP is our mobile app for order processing for maintenance in production. It offers an intuitive interface and is of course offline-capable. mobileX-CrossMIP enables mobile access to plant data, digital creation of feedback, forms and time recording. Material logistics can also be mapped with our mobile app.

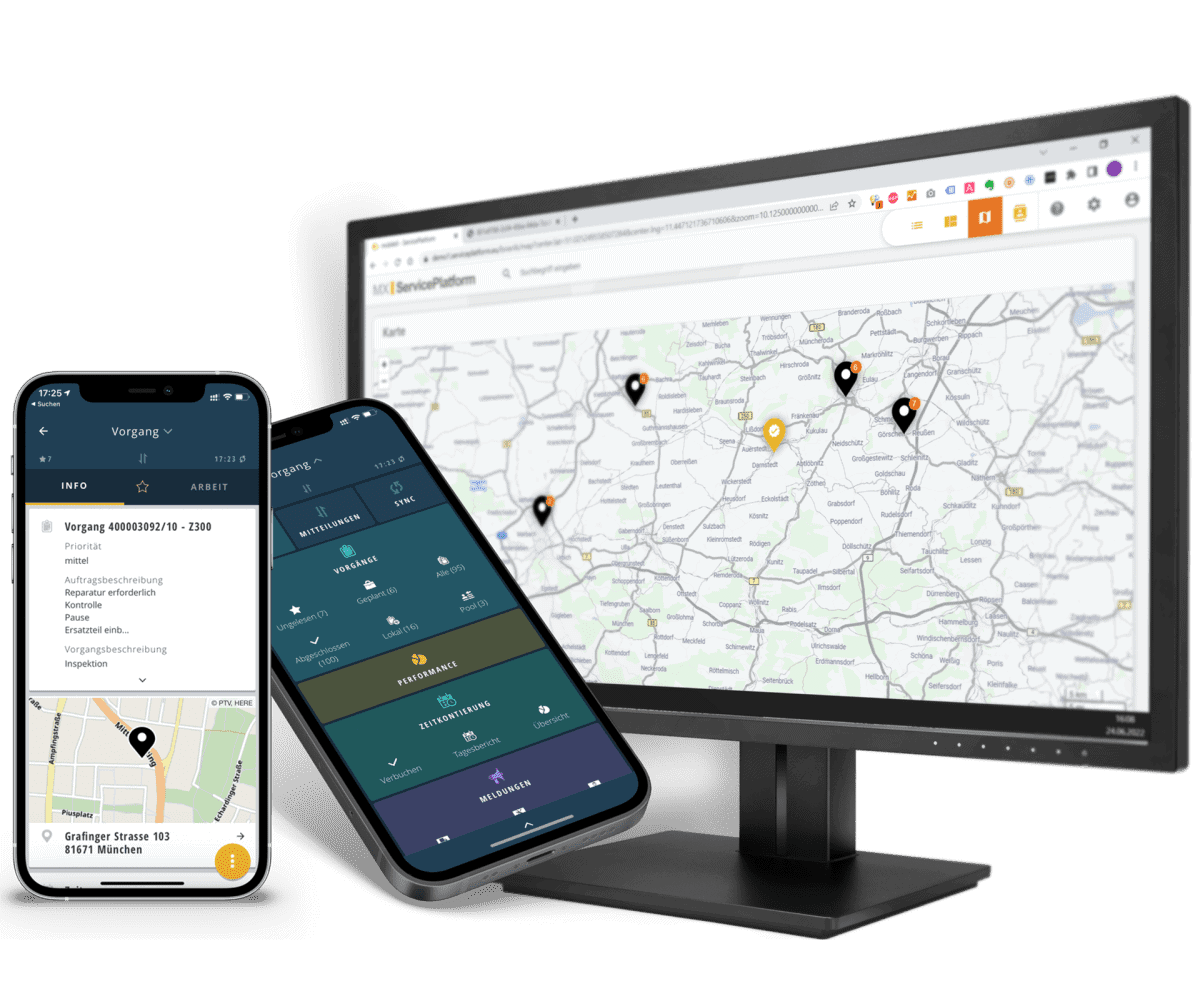

Field Service Cloud

The mobileX-ServicePlatform is mobileX’s public cloud solution for digital deployment planning and order processing of maintenance orders. Our subscription-based model is characterised by simple and fast integration, individual adaptability and an end-to-end digital process for your orders. The mobileX-ServicePlatform is the perfect solution for the fast and flexible digitalisation of your service and maintenance processes.

Our proven maintenance solutions can be used on-premise in the company or conveniently as a cloud solution with maximum availability. Integration into the leading backend systems (SAP PM or others) of companies takes place via dedicated interfaces or web services. In doing so, we adapt our solutions to the individual maintenance and business processes and use cases of companies.

Our maintenance software in companies

The mobileX maintenance software is particularly suitable for companies from the plant and mechanical engineering, production, energy supply, medical technology, facility management, IT and telecommunications industries.

Typical users of our reliable solutions are medium-sized companies and large corporations with mobile maintenance employees. These can be in-house maintenance staff or external forces.

Companies use our maintenance software on a regional and national level (energy suppliers) as well as worldwide (international corporations).

The most important features of our maintenance software

- Clear planning cockpit (Gantt chart)

- Planning of maintenance, inspections and revisions

- Planning of repairs

- Scheduling of operations taking qualifications into account

- Automatic planning

- Pool planning

- Access to backend systems (plant history, details).

- Creation of fault messages

- Maintenance of master data

- Status change

- Feedback with damage images and redlining

- Audit-proof documentation

- Material logistics and picking

- Checklists and forms

- Time recording

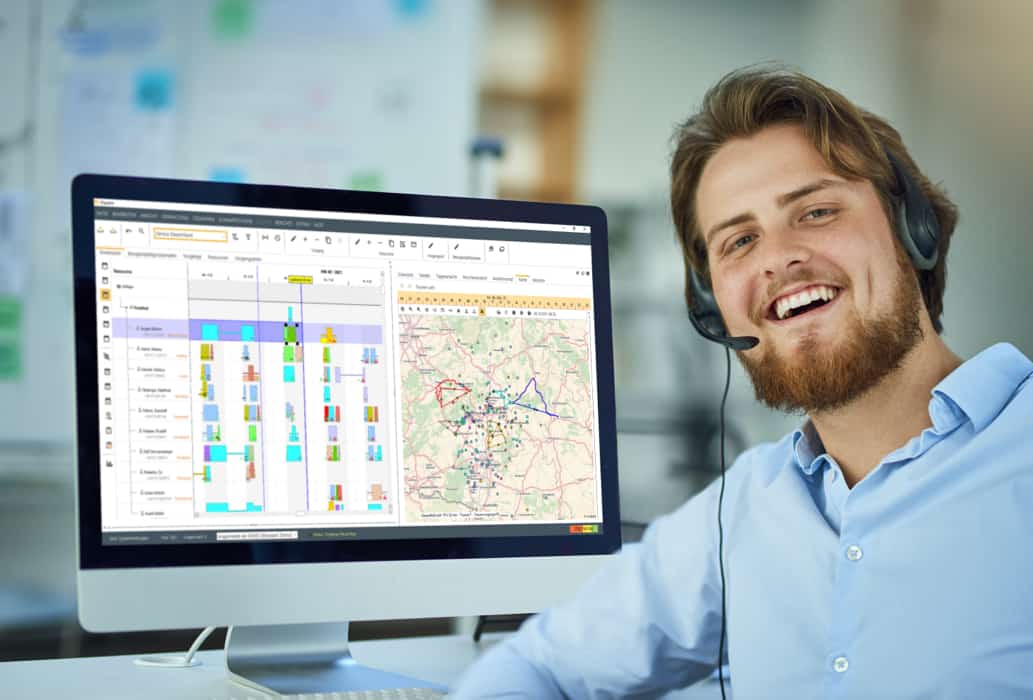

Curious? Arrange a demo now!

- We will show you the functionality of our solutions without obligation.

- Deployment planning software and mobile solution

- Time for your questions

Advantages of our maintenance software

Our sophisticated order planning and mobile maintenance solutions optimize corporate maintenance processes for everyone involved.

Advantages for maintenance managers

- More efficient maintenance processes

- Improvement of data quality

- Higher plant availability

- Increased service life of plant and machinery

- More transparency about maintenance processes

- Better utilization of resources

- Lower maintenance costs

- Audit-proof documentation

- Improved occupational safety

Advantages for dispatchers / maintenance planners

- More efficient planning of maintenance, inspections and repairs

- More transparency about resources and assets

- Fast rescheduling in the event of staff absences

- Fast response in the event of equipment malfunctions

Advantages for maintenance staff

- Maximum information about plants and machines

- More efficient processing of orders

- Avoidance of manual rework and data transfer

- Offline capable processing

Related articles

Customers and references of mobileX

Numerous middle-sized companies and large enterprises from the manufacturing industry, energy supply, healthcare, facility management, IT and telecommunications use our field service management and mobile solutions worldwide.