mobileX-Optimizer - automatic dispatching in mobileX-Dispatch

In addition to manual planning via drag-and-drop, dispatchers can also use the automatic dispatching in mobileX-Dispatch, the mobileX-Optimizer, when planning the operations of their technicians. The fully automatic planning distributes all orders and operations to the available resources – without exceptions and restrictions by the dispatcher. With semi-automatic planning, the dispatcher first specifies a certain period for optimisation. This can be a long period of several weeks and months or just a certain day. Then he defines which types of orders or operations, which locations or resource groups are to be planned or also excluded from automatic planning.

The challenge of optimal route planning

The planning of optimal tours becomes even more demanding the more technicians and assignments are to be planned and the more framework conditions and planning goals have to be taken into account. This is why the allocation of orders to technicians requires a lot of computing time in theory. In computer science, this is called MDVRPTW (Multi Depot Vehicle Routing Problem with Time Windows). This is an NP-completeness problem, i.e. a difficult problem that cannot be completely solved efficiently using today’s computers.

Since the available planning time in daily use is limited and not all possible combinations of operations can be calculated, the mobileX-Optimizer uses certain assumptions (heuristics) to generate sufficiently good tours. Such heuristic procedures are based on experience and can arrive at workable solutions with limited knowledge and in a short time. These are then optimised further and further with regard to the cost function.

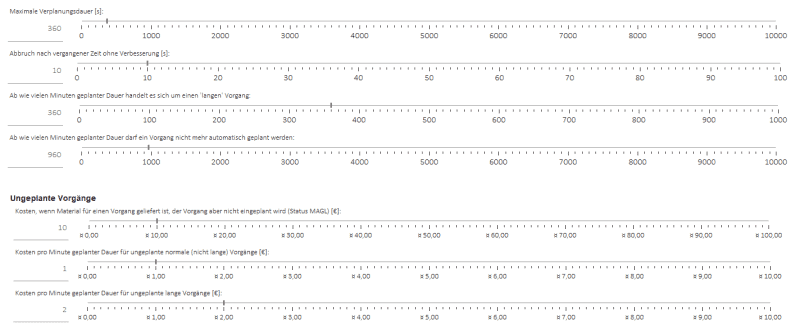

Cost function and parameterisation

In each possible planning scenario, the cost function defines the costs with regard to certain parameters. These are factors that play an important role for a company in planning. These vary from company to company and depend on the individual business, service and scheduling strategy.

The mobileX-Optimizer thus helps to approach an optimum in the distribution of operations. The company describes what the optimum is by assigning certain costs to the individual factors. These can be, for example:

- Every minute that a technician drives costs 3.50 euros.

- Every operation that cannot be scheduled costs 100 euros.

- If the preferred technician cannot be scheduled, then this is a loss of quality for the customer. This is assessed at 50 euros per operation.

- If a process cannot be scheduled within the SLA times, then each hour beyond that costs €20.

The factors of parameterisation, i.e. optimisation with regard to the cost and benefit target values, include, for example:

- Plannable time of the technician

- Location of the technician

- Skills / qualifications of the technician

- Vehicle loading capacities

- Service level agreements

- Agreed times

- Expected duration of operations

Goals of automatic scheduling

The more complex the goal(s) of the operational planning, the more cost parameters influence its achievement. Since these parameters can also be contradictory (shortest versus fastest route), they must be prioritised accordingly and weighted accordingly in the mobileX-Optimizer interface. Possible goals of optimised planning can be:

- Shorter journey times -> optimisation on the fastest route

- Less CO2 pollution -> optimisation on shortest route

- Lower costs -> optimisation on shortest and fastest route, high first-time-fix-rate

- High customer satisfaction -> optimisation for short time windows, preferred appointments, fast appointments, preferred technicians, high first-time-fix rate

- Optimal resource utilisation -> optimisation for little overtime, short travel times, high first-time-fix rate, skill matching

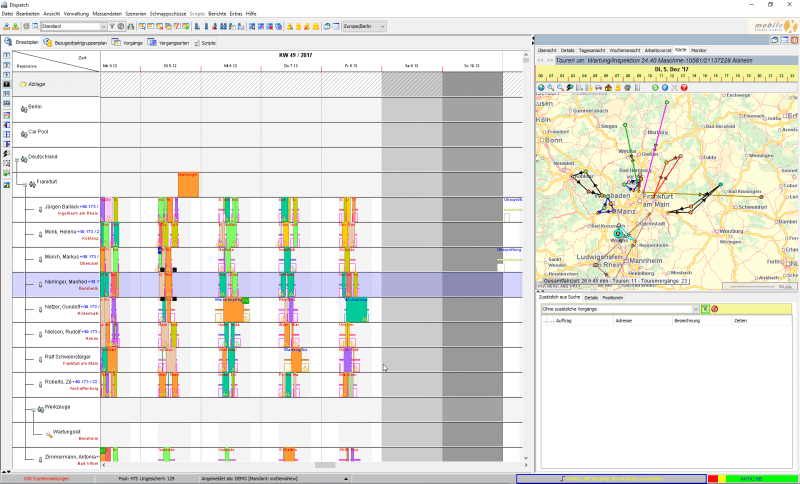

Map integration and calculation of optimal routes

The mobileX-Optimizer uses the digital road map from PTV to calculate the tours. Using the geocoordinates of the starting point and the destinations, the PTV server calculates the distances and thus the travel times for all possible routes. From this, the mobileX-Optimizer calculates the best possible routes according to the cost functions. The calculation includes speed profiles of resources that are stored for certain vehicles. Historical traffic data with time-of-day or seasonal profiles for routes – such as rush hour – can also be taken into account. The goods being transported can also play a role in route planning. For example, if it is a hazardous goods transport, it may only travel on certain roads.