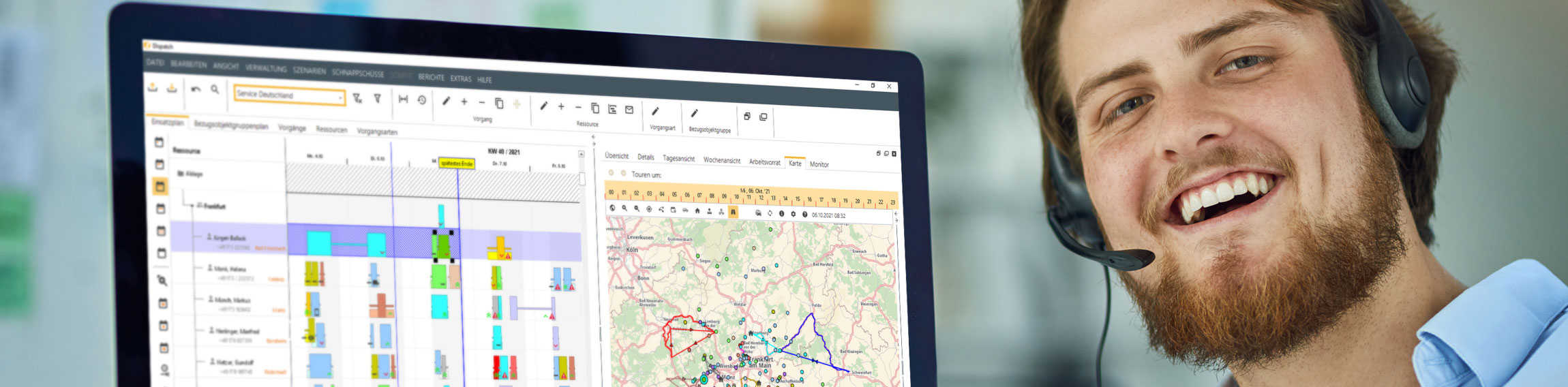

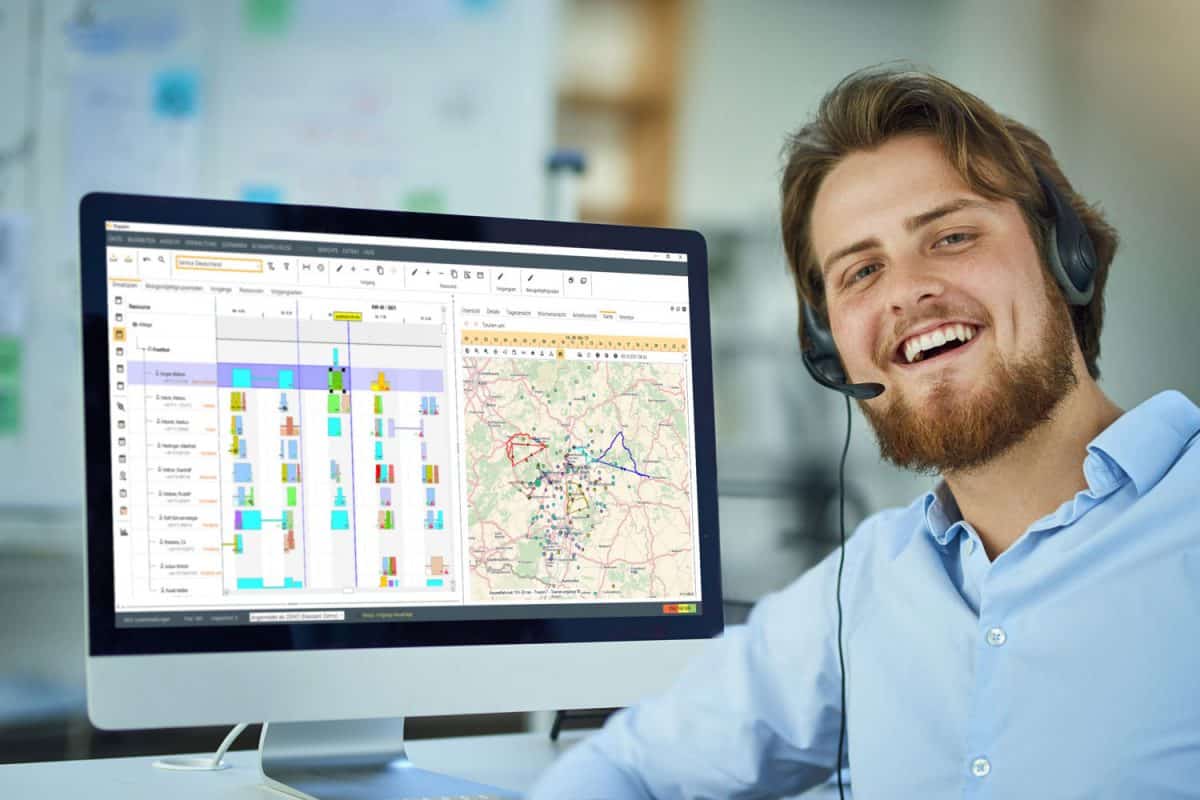

Route planning in technical customer service

What is route planning in technical customer service?

Route planning in technical customer service is a process in which orders are grouped into tours and placed in a specific sequence. These are usually day trips in which a technician is on the road with a vehicle and returns to his starting point in the evening.

Route planning is an essential part of resource planning in technical customer service.

Route planning is an essential part of resource planning in technical customer service.What is route optimization?

The so-called route optimization in a resource planning solution uses an algorithm to calculate the most cost-effective variant for all waypoints with the available resources. What is the most cost-effective option for a company depends on the respective service and planning strategy. This can be the shortest or fastest route, for example. In addition, there are many other optimization parameters that a company should define individually in a cost function.

What is a cost function?

A cost function defines the costs for certain parameters in every possible planning scenario. In addition to the obvious parameters such as travel times between missions and the number of kilometres covered, there are many other factors with which companies can define their individual optimisation.

Other important factors for the cost function are:

- Utilization of employees

- Service Level Agreements (SLAs)

- Priorities

- Time limits

- Load capacities

- Skills

For cost-sensitive companies, savings through route optimization are just as important as the avoidance of empty or second journeys. Material logistics must also be considered here. Thus, dispatchers must also take into account dispatch times for spare parts to the customer’s location. The service technician can only work when the required spare part is available.

Optimization parameters can also be contradictory. This is usually expressed in planning tools by weighting the parameters using cost points using the cost function. This allows companies to define how, for example, an order with high priority is treated over an order with impending violation of time limits.

Route optimization reduces travel costs in technical customer service.

Route optimization reduces travel costs in technical customer service.What are the advantages of a route optimization?

- Optimal use of resources

- Increased customer satisfaction

- More transparent service processes

Which companies use route optimization?

Tools for route optimization are most frequently used in companies that provide customer service or maintenance services for a technically sophisticated product. Companies in the mechanical and plant engineering, medical technology, energy supply, facility management, IT and telecommunications sectors typically use a planning tool with a module for route optimization. The size of the company plays less of a role here than the number of technicians or fitters that are planned. The number of orders at different locations per day and technician and the service strategy are also important here.

Such tools are not suitable for companies in the logistics and CEP industries, as they place different requirements on such a solution.

From how many deployments or ressources planned per day, a route optimization tool pays off?

It is difficult to determine from which planning volume automatic route planning pays off in general and across industries, as this depends heavily on the company’s planning and service strategy. The zoning of sales representatives also plays an important role here. The larger the regions of the individual service technicians are and the higher the distances driven per year, the more time and money can be saved through optimized route planning. Of course, this also applies to the number of technicians or fitters to be scheduled.

As a rough rule of thumb, the use of a solution for 50 or more field service technicians pays for itself in less than two years. You can also find more information about the return on investment in our ROI calculator.

The calculation of optimal routes takes a lot of time.

The calculation of optimal routes takes a lot of time.Why is it so difficult to calculate an optimal route?

How to solve the MDVRPTW in practice?

What makes the implementation of a route optimization project so difficult?

Every company is different and has an individual business, service and planning strategy. That is why it is essential at the beginning of a tour optimization project that all parties involved agree on the optimization factors that influence the cost function. Next, the factors should be weighted accordingly. For example, a company that wants to differentiate itself through particularly good service will prioritize the availability of the most suitable technician for a particular job. Ideally, the degree of fulfilment of each factor can be described in monetary terms.

Some factors will not yet be available digitally at the beginning of such a project, but will only be present in the minds of the planners. Therefore, the knowledge of the employees must first be recorded and taken into account for the algorithms.

What types of automated, tool-supported planning are available?

There are different types of automated planning, depending on how high the level of automation and how complex the planning is in each case. Each of the automated planning procedures allows you to integrate manually planned shifts and “fixed dates” into planning. If these dates are available for one or more technicians, the algorithm adjusts the planning accordingly around these fixed dates.

In scheduling, the tool proposes various options for an order to the MRP controller. He can prioritize between different parameters such as “next possible appointment”, “additional travel time” or “utilization of the technician” and, depending on the company’s scheduling strategy, decide and propose an appropriate appointment to the customer.

In sequence optimization, the orders already scheduled for a technician are arranged with regard to the ideal route sequence. The start and end points can also be different.

In semi-automatic planning, the MRP controller first defines a specific period for optimization. This can be a long period of several weeks and months or just a certain day. It then defines which types of orders or operations, which locations or resource groups are to be planned or excluded from automatic planning.

For companies that schedule many resources and orders daily, planning usually takes place fully automatically at night. The fully automatic system works in the same way as the semi-automatic system, but without any intervention by the dispatcher. The more time the algorithm has to optimize, the better the results in the end. The duration of planning is therefore also one of the optimization parameters that companies should define.

Can route optimization replace the dispatcher?

A tool for route optimization supports dispatchers in their daily planning.

A tool for route optimization supports dispatchers in their daily planning.How can the dispatcher plan on a daily basis?

It often happens that a dispatcher has to reschedule planned tours. Reasons for this can be the illness of a technician, an acute disturbance, or the cancellation of an appointment by the customer. Using a planning tool, the planner always has an overview of the current planning situation and can see which colleague is in the vicinity, has time and is also qualified and can therefore schedule him. However, it is important for this that the technicians report their current status as quickly as possible, ideally using a mobile solution. The MRP controller can then have the tool make suitable proposals for rescheduling.

Through an additional integration of vehicle position data from positioning systems into a tool for resource planning, dispatchers can keep track of the current location of their service vehicles at all times. With the vehicle position data, suitable service technicians can be found quickly and easily in the vicinity of the location in urgent operations. Current traffic data and traffic jam reports in the planning tool enable even more precise route and time planning.

Related articles

mobileX-Dispatch

mobileX-Dispatch ist unser Tool zur Optimierung Ihrer Einsatzplanung für den technischen Kundenservice und Ihrer Auftragsplanung für die Instandhaltung.